Does the metal shell static wrist strap alarm achieve precise sensing, adding a "metal shield" to safety?

Release Time : 2025-11-05

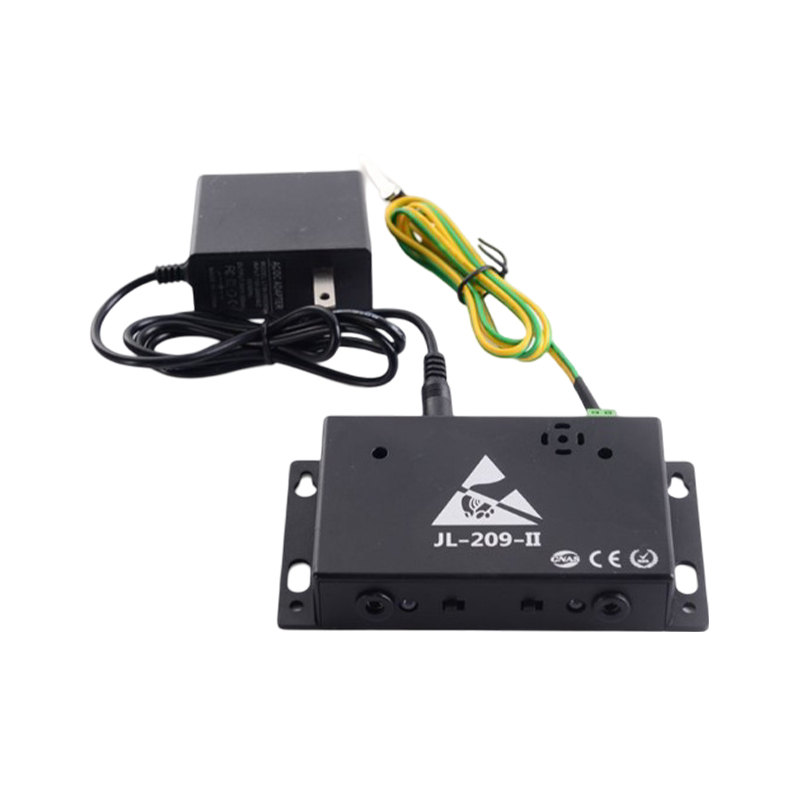

In highly sensitive work environments such as electronics manufacturing, semiconductors, precision instrument assembly, pyrotechnics handling, and cleanrooms, electrostatic discharge from the human body, though imperceptible, can instantly damage valuable components, causing product failure, data loss, or even safety accidents. To effectively control this "invisible killer," a metal shell static wrist strap alarm... The alarm was developed to address this need. It's not just a monitoring device, but a "metal shield" integrating precise sensing, reliable alarm, and robust protection, building the first line of defense for personnel safety and product quality.

1. Precise Real-Time Monitoring: Millisecond-Level Response to Human Grounding Status

The core function of the static wrist strap alarm is to continuously monitor whether the operator is reliably grounded through the anti-static wrist strap. Its integrated high-sensitivity current/resistance detection circuit can determine in real time whether the path between the wrist strap and the human body, and between the grounding wire and the common grounding point, is complete. If the wrist strap becomes loose, broken, has poor contact, or is removed without authorization, the grounding loop resistance will instantly exceed the safety threshold, and the alarm will immediately trigger a response—the response time can reach milliseconds, far faster than manual inspection. This "zero-tolerance" precise sensing mechanism ensures that any electrostatic risk is intercepted before it occurs.

2. Metal Shell: Robust Protection and Electromagnetic Shielding Dual Guarantee

Unlike products with plastic shells, the metal shell static wrist strap... Alarms made of aluminum alloy or stainless steel offer several advantages. Firstly, their high mechanical strength withstands workshop collisions, drops, and tool scratches, making them suitable for harsh industrial environments. Secondly, the metal casing naturally creates a Faraday cage effect, effectively shielding against external electromagnetic interference—preventing false alarms or missed alarms in SMT workshops or RF laboratories with dense high-frequency equipment. Thirdly, the good thermal conductivity of metal facilitates heat dissipation for internal electronic components, improving long-term operational stability. More importantly, the metal casing itself can serve as part of the grounding path, further enhancing system reliability.

3. Multiple Alarm Mechanisms: Visual + Auditory + Remote Linkage, Eliminating Oversights

To ensure alarms are not ignored, high-end metal-cased alarms are typically equipped with dual audible and visual alarms: high-brightness LED flashing lights combined with 85 Buzzers with a dB or higher frequency can attract attention even in noisy environments. Some smart models also support relay output or RS485/Modbus communication interfaces, enabling linkage with access control systems, production line PLCs, or central monitoring platforms to achieve digital management of ESD protection. This "local + remote" collaborative mechanism minimizes reliance on human intervention, truly achieving a combination of "human and technological prevention."

4. Compliant with International Standards, Safeguarding Compliant Production

The metal shell static wrist strap alarm's detection accuracy, alarm threshold, and grounding resistance range have all undergone authoritative certification. In highly regulated industries such as automotive electronics, medical equipment, and aerospace, this type of equipment is not only a process assurance tool but also essential hardware for meeting quality system audits. Its metal casing design also facilitates regular inspection and calibration, ensuring long-term compliance.

Metal shell static wrist strap alarm, with its precision electronics as "eyes" and robust metal as "shield," constructs a silent yet reliable protective barrier in electrostatic-sensitive areas. It monitors more than just the continuity of a wristband; it safeguards product yield, production line stability, and the company's reputation. In today's increasingly prevalent intelligent and high-reliability manufacturing landscape, this seemingly small device, with its precision, robustness, and intelligence, is becoming an indispensable "safety sentinel" in modern ESD protection systems—ensuring every operation proceeds precisely along a safe path.

1. Precise Real-Time Monitoring: Millisecond-Level Response to Human Grounding Status

The core function of the static wrist strap alarm is to continuously monitor whether the operator is reliably grounded through the anti-static wrist strap. Its integrated high-sensitivity current/resistance detection circuit can determine in real time whether the path between the wrist strap and the human body, and between the grounding wire and the common grounding point, is complete. If the wrist strap becomes loose, broken, has poor contact, or is removed without authorization, the grounding loop resistance will instantly exceed the safety threshold, and the alarm will immediately trigger a response—the response time can reach milliseconds, far faster than manual inspection. This "zero-tolerance" precise sensing mechanism ensures that any electrostatic risk is intercepted before it occurs.

2. Metal Shell: Robust Protection and Electromagnetic Shielding Dual Guarantee

Unlike products with plastic shells, the metal shell static wrist strap... Alarms made of aluminum alloy or stainless steel offer several advantages. Firstly, their high mechanical strength withstands workshop collisions, drops, and tool scratches, making them suitable for harsh industrial environments. Secondly, the metal casing naturally creates a Faraday cage effect, effectively shielding against external electromagnetic interference—preventing false alarms or missed alarms in SMT workshops or RF laboratories with dense high-frequency equipment. Thirdly, the good thermal conductivity of metal facilitates heat dissipation for internal electronic components, improving long-term operational stability. More importantly, the metal casing itself can serve as part of the grounding path, further enhancing system reliability.

3. Multiple Alarm Mechanisms: Visual + Auditory + Remote Linkage, Eliminating Oversights

To ensure alarms are not ignored, high-end metal-cased alarms are typically equipped with dual audible and visual alarms: high-brightness LED flashing lights combined with 85 Buzzers with a dB or higher frequency can attract attention even in noisy environments. Some smart models also support relay output or RS485/Modbus communication interfaces, enabling linkage with access control systems, production line PLCs, or central monitoring platforms to achieve digital management of ESD protection. This "local + remote" collaborative mechanism minimizes reliance on human intervention, truly achieving a combination of "human and technological prevention."

4. Compliant with International Standards, Safeguarding Compliant Production

The metal shell static wrist strap alarm's detection accuracy, alarm threshold, and grounding resistance range have all undergone authoritative certification. In highly regulated industries such as automotive electronics, medical equipment, and aerospace, this type of equipment is not only a process assurance tool but also essential hardware for meeting quality system audits. Its metal casing design also facilitates regular inspection and calibration, ensuring long-term compliance.

Metal shell static wrist strap alarm, with its precision electronics as "eyes" and robust metal as "shield," constructs a silent yet reliable protective barrier in electrostatic-sensitive areas. It monitors more than just the continuity of a wristband; it safeguards product yield, production line stability, and the company's reputation. In today's increasingly prevalent intelligent and high-reliability manufacturing landscape, this seemingly small device, with its precision, robustness, and intelligence, is becoming an indispensable "safety sentinel" in modern ESD protection systems—ensuring every operation proceeds precisely along a safe path.